Rust and corrosion are persistent foes of metal surfaces, causing damage, weakening structures, and diminishing aesthetics over time. Fortunately, blast cleaning emerges as a powerful solution to combat these adversaries and restore metal surfaces to their former glory. In this blog post, we’ll explore the specific benefits of blast cleaning for metal surfaces, focusing on its effectiveness in removing rust and corrosion. Through before-and-after examples, we’ll showcase the transformative effects of blast cleaning on metal structures, machinery, and equipment.

Benefits of Blast Cleaning for Metal Surfaces:

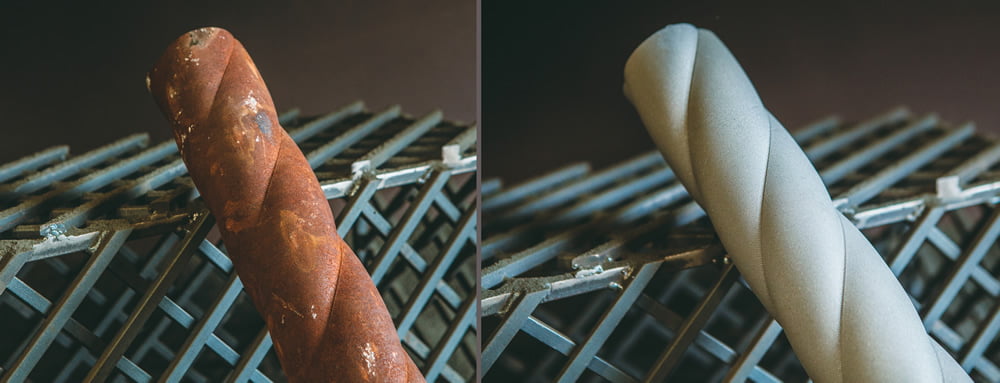

- Efficient Rust Removal: Blast cleaning techniques, such as sandblasting and shot blasting, are highly effective in removing rust and corrosion from metal surfaces. The abrasive particles or media used in blast cleaning penetrate deep into the rust layers, breaking them down and revealing the clean metal underneath.

- Surface Preparation: Beyond rust removal, blast cleaning prepares metal surfaces for further treatment or coating applications. By removing contaminants, scale, and old coatings, blast cleaning creates a clean and smooth surface, ensuring optimal adhesion and longevity of protective coatings.

- Versatility: Blast cleaning can be tailored to suit different types of metal surfaces and rust levels. Whether it’s heavy corrosion on industrial machinery or light rust on decorative metalwork, blast cleaning techniques can be adjusted to achieve the desired results without causing damage to the underlying metal.

- Cost-Effectiveness: Compared to traditional methods of rust removal, such as manual scraping or chemical treatments, blast cleaning offers a more efficient and cost-effective solution. It reduces labor time and minimizes the need for harsh chemicals, resulting in savings on both time and resources.

Transformative Effects of Blast Cleaning:

- Industrial Machinery: Blast cleaning breathes new life into industrial machinery by removing layers of rust and corrosion that hinder performance and reliability. From heavy equipment to intricate machinery parts, blast cleaning restores functionality and extends the lifespan of valuable assets.

- Structural Components: Metal structures, such as bridges, railings, and pipelines, are susceptible to rust and corrosion due to exposure to the elements. Blast cleaning revitalizes these structures, improving their appearance, durability, and structural integrity for years to come.

- Automotive Restoration: Blast cleaning plays a crucial role in automotive restoration projects by removing rust from vehicle chassis, panels, and components. Whether it’s a classic car undergoing restoration or a fleet of commercial vehicles in need of maintenance, blast cleaning enhances their appearance and value.

Before-and-After Showcase:

Conclusion: Rust and corrosion may seem like formidable adversaries for metal surfaces, but with blast cleaning, their grip can be effectively loosened. By efficiently removing rust, preparing surfaces, and revitalizing metal structures and equipment, blast cleaning proves to be an invaluable asset in the maintenance and preservation of metal surfaces. Say goodbye to rust and hello to rejuvenated metal surfaces with the transformative power of blast cleaning.

Ready to restore your metal surfaces to their former glory? Contact us today to schedule a blast cleaning service and experience the difference firsthand.